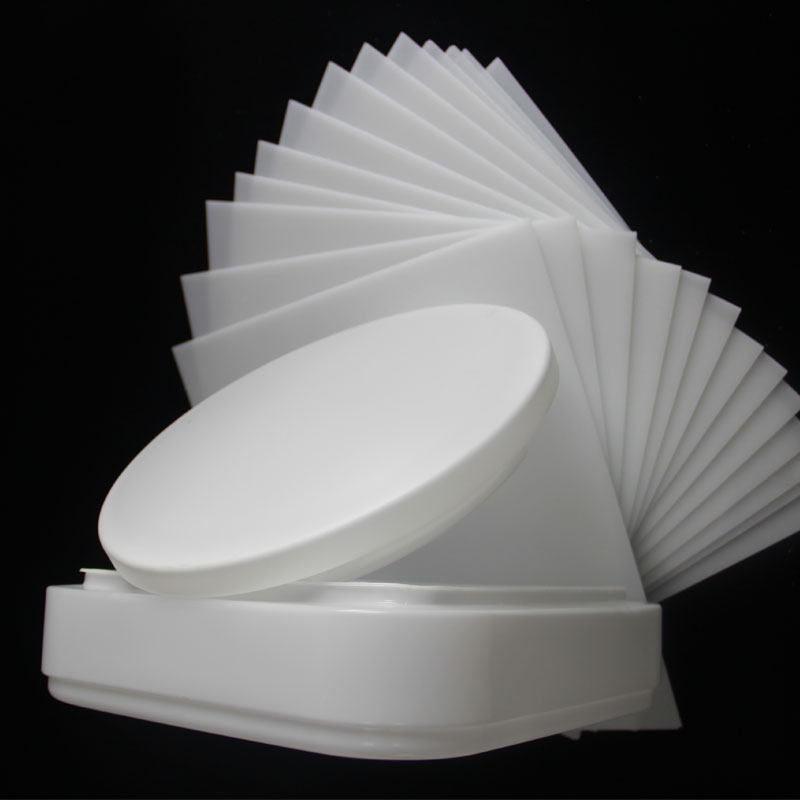

China Mirror Acrylic Sheet Factory will give you an introduction to the characteristics and technical specifications of the PMMA diffuser.

1. Features

High brightness: At the same penetration rate, brightness can be improved compared to conventional diffusers.

Excellent shielding effect: the light source has good diffusion and homogenization ability, and the effect of shielding the lamp is excellent.

High dimensional stability: low water absorption warpage and excellent dimensional stability.

Excellent durability: It is not easy to have yellowing in the accelerated test of ultraviolet aging.

Excellent quality assurance: All series of products have passed the UL-94 and RoHS banned poison test.

2. Technical indicators

Specific gravity: ASTMD792 ---- 1.2

Simply supported beam impact strength: ASTMD256 KL/m2 ≥16

Elongation at break: ASTM D638 % ≥ 2

Tensile yield stress: ASTMD638 MPa ≥66

Heat distortion temperature: GB1634 °C ≥85

Longitudinal shrinkage: WZ-YF-JYQB-025 % ≤5

Transverse stretch ratio: WZ-YF-JYQB-025 % ≤3

Water absorption rate: GB1638 % ≤0.3%

Light transmittance: haze test instrument: 60%-90% (range adjustable)

Haze (Reference): Glow test equipment: 88%-98% (range adjustable)

Our company specializes in PMMA Acrylic Sheet, please feel free to contact us if you need it.

评论

发表评论