The types of Diffuser sheets can be divided into gas diffusion plates, sound diffusion plates, liquid diffusion plates, diffuser sheets, taste diffusion plates, and materials capable of uniformly dispersing molecules are collectively referred to as diffuser sheets.

How does the diffuser sheet work, why can it be used diffusely? To know this, we need to know how the diffuser sheet works. The diffusion board works as follows.

Before understanding the diffusion principle of the diffuser sheet, you must first know two principles, one is the reflection principle and the other is the refraction principle. The principle of reflection is that when light strikes a smooth interface from one medium to another, part of the light is reflected by the interface and another part of the light is refracted through the interface in the other medium. The angle of incidence of the light is equal to the angle of reflection, and the reflected light is on either side of the normal to the incident plane in the same plane. The principle of refraction is that the refracted ray is located in the plane of the incident light and the normal, the refracted light and the incident light are on both sides of the normal, and the ratio of the incident angle to the sine of the angle of refraction is a constant.

LED Lighting Diffuser Sheet, a principle like this, can be widely used in liquid crystal display, LED lighting and imaging display systems.

Diffuser sheet shows its characteristics in liquid crystal display

Diffuser sheet is one of the main applications in liquid crystal display. The application of diffuser sheet in liquid crystal display is mainly due to its heat resistance, flame resistance, light transmittance and other advantages, followed by the performance of diffuser sheet in liquid crystal display. The characteristics that come out, let's talk about these performance characteristics.

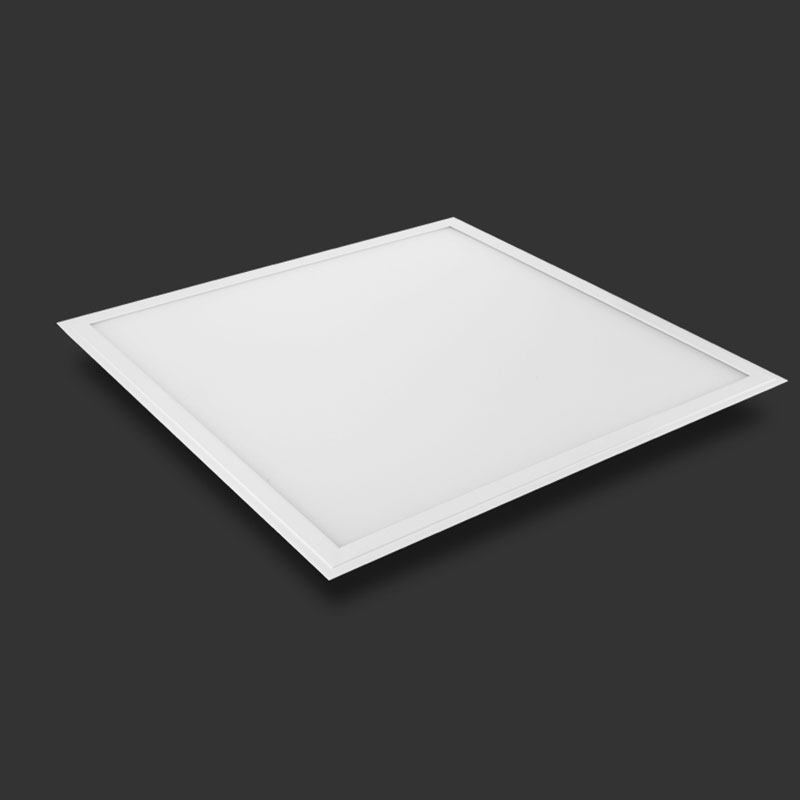

Diffuser Sheet for LED Panel Light

1. Light source diffusibility: Suitable for direct-lit backlight modules, with high brightness and high diffusivity, which can improve the uniform diffusion effect of the backlight.

2. Light transmittance: Excellent light transmittance occurs with high brightness.

3. Dimensional stability: minimum water absorption, good dimensional stability in wet environment, and normal use in the temperature range of -40 ° C ~ 125 ° C.

4. Antistatic property: It has good antistatic performance and prevents dust from adsorbing.

This is the performance of the diffuser sheet on the LCD display. It is precisely because of these characteristics that the light diffuser is selected in the liquid crystal display.

The main application of the Diffuser sheet is on LED lighting and liquid crystal display, which is used to fully scatter the incident light for a softer and evener illumination. However, LED lighting has certain requirements for the use of diffuser sheets. The main requirements are as follows.

Requirements for Diffuser Sheet for LED Panel Light for LED lighting:

1. The best diffusion performance: high softness of light.

2, high light transmission performance: reduce energy consumption, improve the illumination of the lamps.

3. Influence on the light source: Maintain the consistency of the color temperature of the light source.

Therefore, if it is to be applied to the LED lighting source, the diffuser sheet should be purchased according to the above LED lighting.

Our company is China Led Diffuser Plate Supplier, welcome to come to us.

评论

发表评论