The light diffuser may be somewhat unfamiliar to some outsiders, but it has been widely used in many fields like the LED diffuser, PS UGR Diffuser. Then the Lighting Diffuser Factory performs a simple analysis of the light diffuser.

Today, we mainly analyze the production principle of light diffusing plates. When we understand its production principle, it can be applied more conveniently.

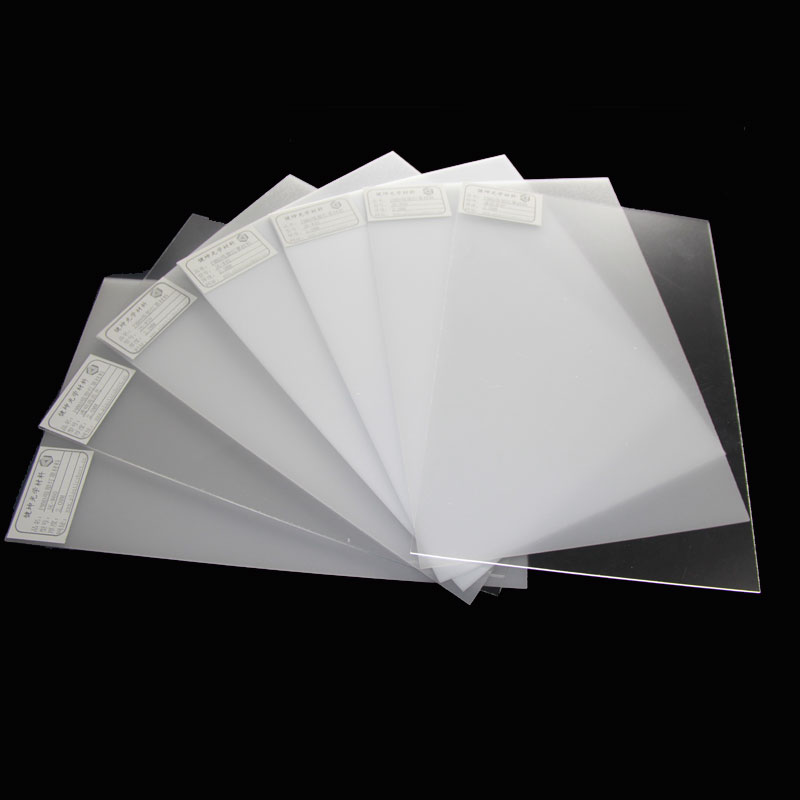

PMMA Acrylic Sheet

Then the light diffusing plate is mainly processed by some process means, and the principle of utilization is mainly: when the light encounters an object whose density is not equal during the irradiation process, it will form reflection or refraction. Then the light diffusing plate, led diffusing plate, etc. use this principle, and then pass some basic plates, such as: PP, PS, etc., because the light can reflect or refract the range is small, so we can be on the surface of the plate Add some diffusing agent so that you can view it from multiple angles and more comprehensively.

Of course, we can also use its principle to achieve artificially change the light emission path, which can satisfy more of our effects.

Our company specializes in providing light diffusing plates such as PMMA Acrylic Sheet. If you would like more information, please feel free to contact us.

评论

发表评论