Uncomfortable glare in rooms or locations commonly used in industrial and public buildings should be evaluated using the Uniform Glare Value (UGR). The UGR value is calculated by the formula. UGR values are divided into seven, 28, 25, 22, 19, 16, 13, 10 and so on. 28 is just unbearable value, 25 is uncomfortable value, 22 is just uncomfortable value, 19 is the limit value of feeling comfortable and uncomfortable, 16 is just acceptable value, 13 is just glare value, 10 is no Glare value. Most of the illuminance standards use UGR values of 25, 22, and 19.

UGR <19

In order to get a comfortable, high-quality lighting environment, it is necessary to suppress glare by improving the luminaire. In recent years, indoor lighting lamps exported to the European union have anti-glare standards, that is, UGR <19, or even lower. In fact, as early as 1995, CIE (International Commission on Illumination) has proposed the concept of anti-glare for lamps, and used Unified Glare Rating as an indicator to evaluate the uncomfortable glare of indoor lighting environment. With the development of LED chip technology, LED lamps are getting brighter and brighter, and uncomfortable glare is becoming more and more serious. So in 2014, the EU adopted the UGR limit as a mandatory standard for luminaires, rather than just as a reference.

The so-called "UGR<19" is only sufficient to meet the most basic glare requirements of schools and office spaces. In fact, in actual use, customers will still prefer UGR smaller lamps. If you look at the correspondence table between the UGR value and the degree of uncomfortable glare, you will know that UGR=19 is actually uncomfortable. The smaller the UGR value of the work and study places, the better.

Many people have a misunderstanding about UGR, which is the same as power and light efficiency. In fact, the meaning of UGR is the discomfort of the lighting environment to the human eye. It is a value calculated by various parameters related to glare to characterize the degree of discomfort glare of the entire lighting space. Simply put, the UGR value is not only related to the luminaire, it is related to the size of the room, the reflectivity of the room, and the direction of the observer's observation.

If you first see the UGR calculation results table, everyone will wonder, which value represents UGR. In fact, each value in the table is the value that the luminaire obtained through the UGR calculation model in the corresponding room environment.

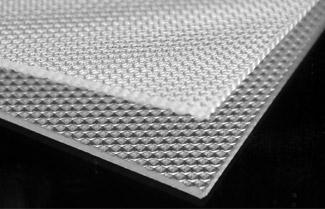

The UGR of the luminaire is not a single value, it is related to the environment in which the luminaire is used. Take the current 600 x 600mm panel light of Led Diffuser Plate as an example. Its use is usually office space and school. The room size is usually 4H8H. The reflectivity of the room is usually the first column, 70% of the roof. 50% and 20% on the ground. Therefore, for such large-sized panel lights, the applicable value of UGR is generally the first column of 4H8H.

Some customers will require the entire table UGR <19, which means that the customer is not sure about the final use environment of the luminaire, then the luminaire must meet the UGR limit in any environment. This is also a very demanding requirement. Our company is UGR<19 Supplier, welcome everyone to come to us.

评论

发表评论