In recent years, the domestic Optical Plastic for Led Panel Light market has undergone rapid development, and has made great progress in technology, scale and products. However, due to the low barrier to entry and the lack of industry standards, the performance of LED panel lamp products in the industry is uneven. The phenomenon of quality is serious, and the price war has also brought some enterprises into the quagmire of “price-for-price”.

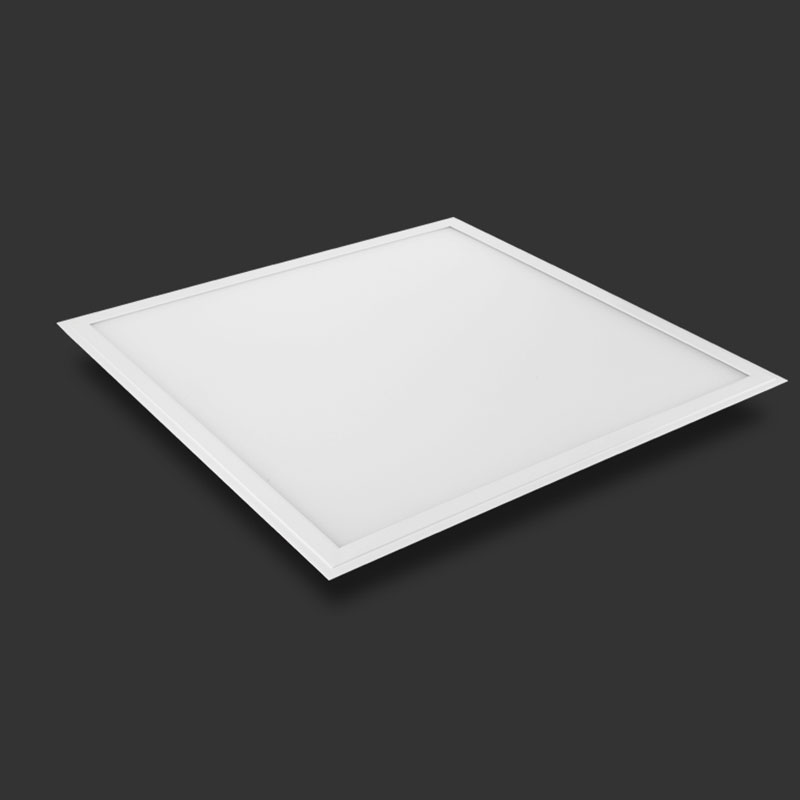

With the development of society, people's living standards have improved, ordinary panel lights can no longer meet the needs of people to pursue a green and environmentally friendly living environment. In recent years, the development of Diffuser Acrylic Sheet, LED panel light technology development, energy saving, high brightness, Long life, no mercury, no stroboscopic, no thermal effect, no pollution, no radio interference, uniform illumination, saving the advantages of decoration space, subverting the luminous characteristics of traditional light sources, can completely replace the traditional T8 engineering lamp panel, widely Used in office, home and other places, market demand continues to expand. However, due to the vicious competition in the market price of panel lights, a large number of unqualified products have been listed, which has violated the real value of LED panel light energy saving, long life and environmental protection, which violates the significance of applying LED technology to the panel light field and seriously affects it. The healthy development of LED panel lights.

Chen Haihui said that the LED lighting industry is expected to continue the reshuffle of the survival of the fittest in 2016. In this process, it should consciously guide the establishment of industry standards and regulations, and form an orderly market competition mechanism. In the LED panel light market, high-quality, innovative companies will develop better, and companies without features and capabilities will lose market competitiveness and eventually be eliminated by the market.

评论

发表评论