With the improvement of the quality of life, people are increasingly pursuing a more comfortable and friendly living environment. The lighting industry is also facing the comfort from the previous attention to the brightness and now more and more attention to lighting, thus promoting friendly, environmentally friendly lighting. Development and application, where UGR<19 is a psychological parameter of the subjective response of the light emitted by the illumination device to the human eye causing comfort and discomfort. China Acrylic Sheet Factory has been operating optical materials for many years. Now combined with its experience and knowledge, it has compiled relevant knowledge about UGR.

First, the UGR definition

UGR is the abbreviation of Unified Glare Rating, which means uniform glare value. It is a psychological parameter that measures the subjective reaction of the light emitted by the illumination device in the indoor visual environment to the human eye, and the magnitude can be calculated according to the prescribed calculation condition using the CIE unified glare value formula. The UGR values are different, and the lighting effects are obviously different. The visual and psychological differences are also large, and the specific use places are also different, as follows:

1, UGR=13, for just feeling glare, the light curtain reflects less, the space ceiling is dark; generally used in computer room, monitoring room.

2,16<UGR<19, just acceptable, for comfort and uncomfortable boundaries, limited control of glare, light curtain reflection, is the first choice for comfortable office space; generally used in ordinary, high-end office, library reading room, hospital, School buildings, etc.

3, UGR>19, just for the uncomfortable, the lighting space is full of vitality, but the glare and light curtain reflection are attractive; generally used for commercial building lighting, business halls, etc.

Second, the UGR control method

1. Avoid installing the luminaire in the interference zone;

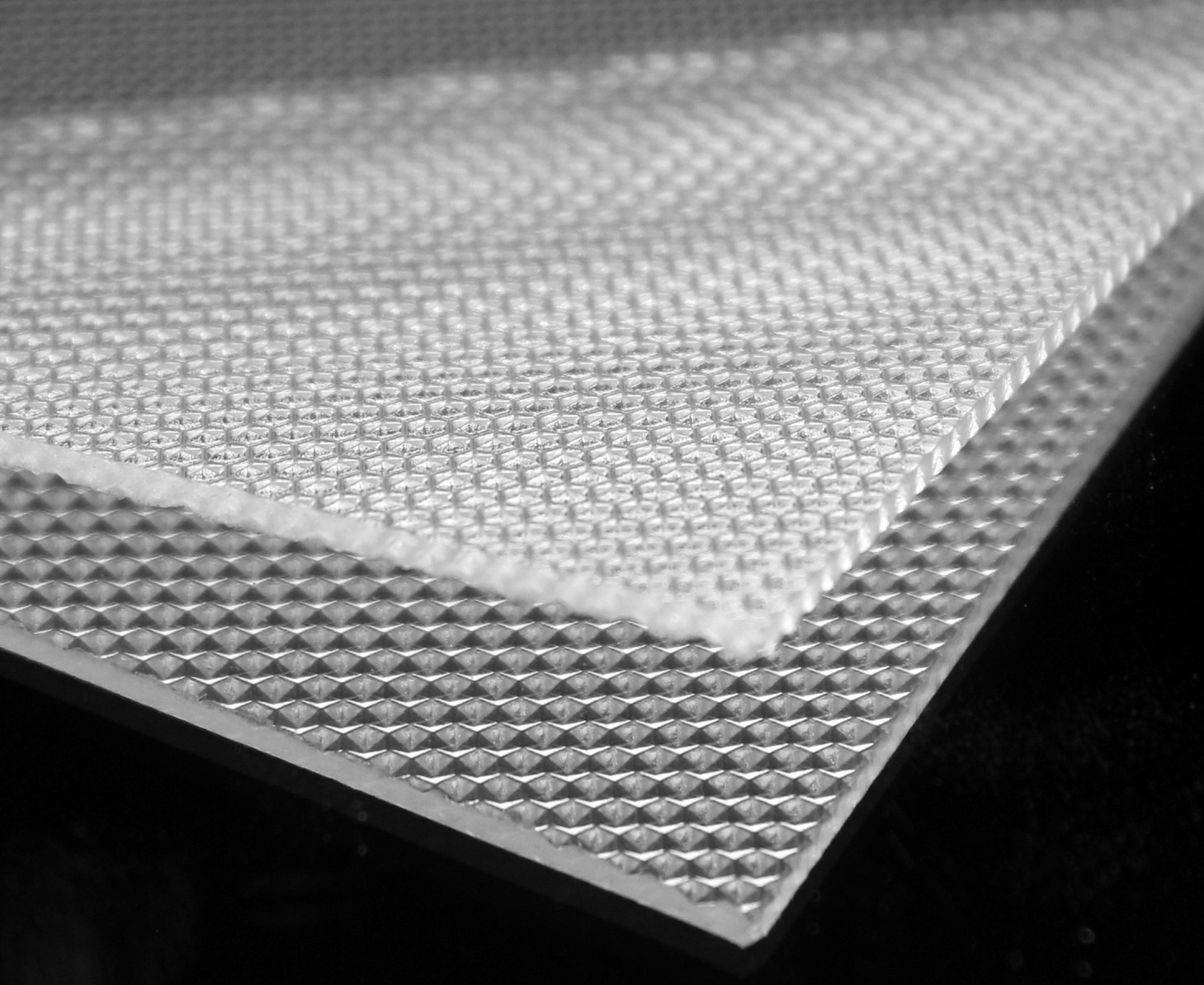

2, using low gloss surface decoration materials, such as UGR diffuser;

3, limit the brightness of the lamp

评论

发表评论