G-Series Microstructure Anti-Glare Film Optical Function: Eliminate high angle light (glare)? Enhance center effective light? Reduce UGR value and help lamps meet ANSI/IESNA RP-1-04 and EN12464 office/indoor Reducing Glaring standards.

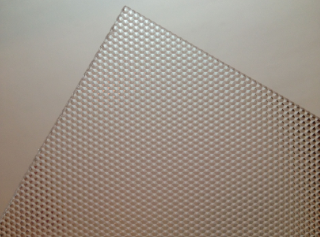

G-series anti-glare films are all PET substrates and contain the following two thicknesses: PET thickness 3 mil (0.075 mm) plus total microstructure thickness of about 0.1 mm. Product Code: G-Gxxx-PE03-SM; PET thickness 7 mil (0.175mm), plus the total thickness of the microstructure is about 0.2mm. Product Code: G-Gxxx-PE07-SM; The above products are all made in the United States, the product is in the form of coil, 82 sheets per roll, each size is 610mm x 1830mm. The 7mil PET substrate has a UL fire rating of VTM-2 and a glow wire test of >750 degrees Celsius. Local dealers can tailor the size to the customer's needs. G-Series Microstructure UGR<19 Diffuser Sheet: The Diffuser Sheet for UGR Solution is a 3mil PET anti-glare film that is bonded to a transparent substrate. The transparent substrate is usually PC or PMMA. PC substrate general thickness: 0.25mm, 0.5mm, 0.75mm, 1mm, 1.2mm, 1.5mm, 2mm... PMMA substrate general thickness: 1.5mm, 2mm, 3mm... Substrate thickness, UV resistance and fire rating can be customer specified. Local distributors are responsible for the bonding process and quality control. Side light panel light installation method ---- Use single layer BVT anti-glare film / board

Note: In all installations, the C-HE80 and the anti-glare microstructured surface must face away from the source, ie the microstructured side faces outward. Straight down panel light installation method ---- Use single layer BVT UGR19 Anti Glaring Diffuser Sheet.

评论

发表评论