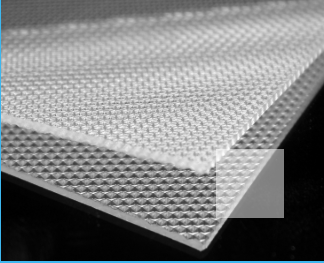

J.K OPTICAL is Specializing in the production and processing of various lamps special Diffuser Sheet, tread plate, main downlight diffuser, panel light diffuser, outdoor light special board, LED panel light / LED flat light / LED downlight special light diffuser and borderless panel light board.

Here is UGR<19 Diffusing Sheet Application Field,

1. UGR<19 Diffusing Sheet is used as a light-transmitting and uniform light-emitting panel for various light-emitting products. Such as light boxes and illuminating signage and other advertising products; merchandise display cabinets, display stands, bars, lamps and so on. It is made into various shapes of light source cover, light source cover, etc. by heat processing, and it is used for various indoor and outdoor lighting projects with special-shaped design.

2. Led Diffuser Plate is used as decorative materials for exhibitions, commercial spaces and home decoration to create special lighting effects. Such as luminous ceilings, walls, cultural walls, image walls, partition walls, etc.

The diffused board and transparent board produced by our company use new imported raw materials, quality and quantity, competitive price, perfect after-sales service, serving all kinds of companies, determined to build the largest and most professional Diffuser Sheet Supplier in China of LED diffuser industry.

评论

发表评论