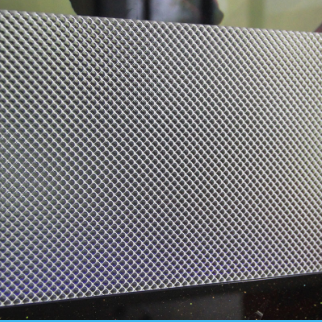

Prismatic Diffuser Panels are produced from high excellent polycarbonate resin blended with a UV stabiliser that's added to improve the life span of this sheet under fluorescent light requirements. The Prismatic Panel are extruded with the P12 design angled female prism matrix around the base surface. The surface is smooth rendering it more suited to vacuum forming, molding and molding; they may also be cut with a circular saw. All these diffuser panels are widely utilized in light applications or as a top excellent flame retardant diffuser.

Key Characteristics of Prismatic Panels

Temperature: Up to +90°C.

Outstanding UV resistance.

Adaptive and impact resistant.

Outstanding light diffusion properties.

By the way, we are a mature Prismatic Panel Exporter in China, call us now, and we will give you the better advice.

评论

发表评论