With the accelerated evolution of the lighting business, and also the improvement of people's living standards, lighting are no more straightforward lighting resources, lamps are popularized to all walks of life, enjoying many different different functions, for example medical lighting, decorative lights, and industrial lights, etc.

Obviously, although the lamp is widely used, in addition, it reveals a whole lot of issues, like heat dissipation, watertight, protection, mild impact, light angle, brightness, UGR<19 and so forth.

Now China UGR<19 Supplier will discuss UGR(Unified Glare Rating) with you.

Regions of high brightness directly alongside areas of low lighting cause warmth, making people uneasy. For example, having a bare light bulb to your desk lamp can provide more than sufficient lighting. But it might cause more light to shine into your eyes than reflects off the background, which makes it hard to read or perform other jobs. Possessing a color on the lamp retains the light from glaring to your eyes while still brightly lit your desktop.

The reduction of warmth is a light which reduces visual functionality and visibility and is frequently accompanied by discomfort.It is principally as a result of stray light in the high brightness origin within the area of vision to the eye, scattering in the eyeball and inducing the picture sharpness and contrast of this retina.The reduction of glare is quantified by the proportion of the visibility of a project under a given lighting into the visibility of its mention lighting, known as the DGF.

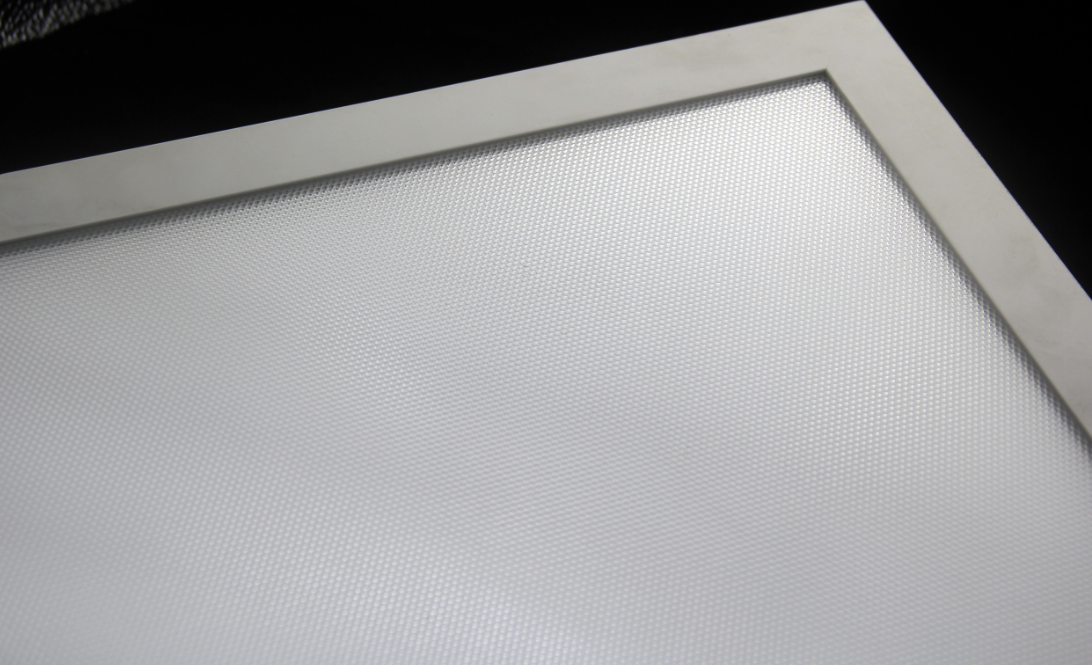

The above two types of glare are known as UGR (Unified glare Rating), especially the coordinated glare significance, is among the primary contents of lighting quality test in lighting design. With this scientific advancement, UGR Diffuser Sheet appeared.

评论

发表评论