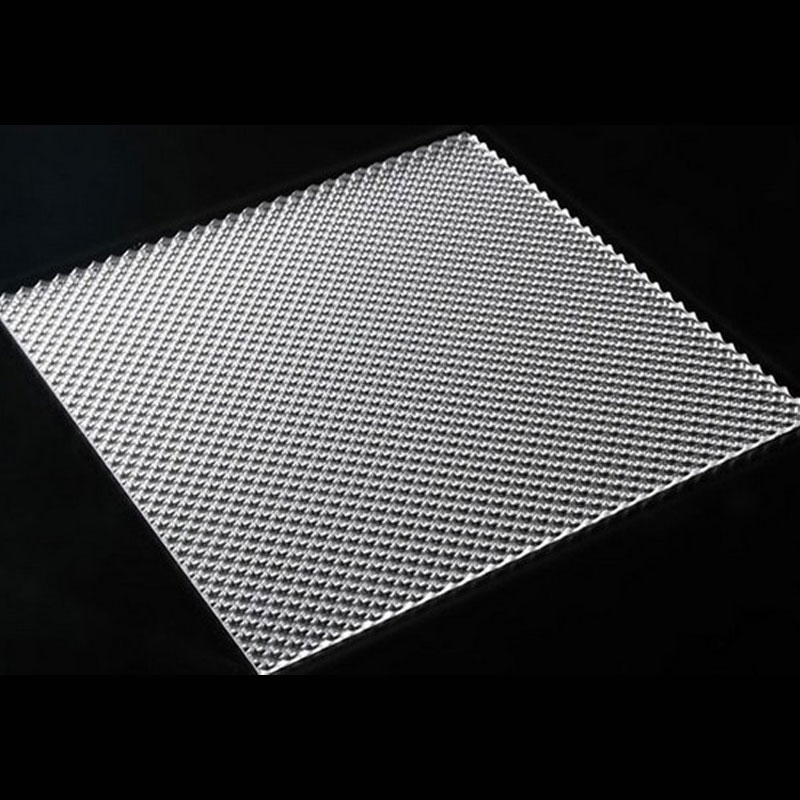

As a China Acrylic Sheet Manufacturer, let us introduce the use of acrylic sheets.Acrylic is the best new material that can be used to make sanitary ware after ceramics. Compared with traditional ceramic materials, acrylic has the following advantages in addition to unparalleled high brightness: good toughness and not easy to break; strong repairability, just use a soft foam to remove the toothpaste to wipe the sanitary ware; soft texture, winter There is no sense of cold and biting; the color is bright, which can satisfy the individual pursuit of different tastes. Acrylic basins, bathtubs, and toilets are not only beautiful in style, durable, but also environmentally friendly. Their radiation levels are similar to those of the human body. Acrylic sanitary ware first appeared in the United States and has occupied more than 70% of the entire international market. Because acrylic production is difficult and costly, there are many low-cost and low-cost substitutes on the market. These substitutes are also known as "acrylic" and are actually ordinary organic boards or composite boards (also known as sandwich panels). Ordinary organic plates are cast with common plexiglass cracking materials and pigments. The surface hardness is low and easy to fade. After polishing with fine sand, the polishing effect is poor. The composite board has only a thin layer of acrylic on the surface, and the middle is ABS plastic, which is easily delaminated by the expansion and contraction during use. True and false acrylic, which can be identified from the subtle chromatic aberration and polishing effect of the Acrylic Pattern Sheet.

1. Building applications: window, soundproof windows and doors, lighting cover, telephone booth, etc.

2. Advertising applications: light boxes, signboards, signs, exhibition stands, etc.

3. Traffic applications: trains, cars, and other vehicle doors and windows, etc.

4. Medical application: baby incubator, various surgical medical equipment, civilian supplies: bathroom facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial applications: instrument surface plates and covers, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lamp covers, etc.

评论

发表评论