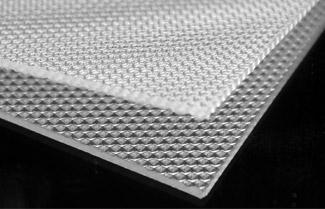

As a PMMA Diffuser Sheet Manufacturer, share the information with you. The light diffusion plate is a physical phenomenon of refraction, reflection, and scattering that occurs when light encounters two media with different refractive indices (densities) on the way through chemical or physical means. Through PMMA, PC, PS, PP , Inorganics or organic light diffusing agents are added to substrates such as hips, or the array of micro-features on the surface of the substrate is used to artificially adjust light, causing light to be refracted, reflected, and scattered in different directions, thereby changing the path of light , To achieve sufficient dispersion of incident light to produce the effect of optical diffusion, there are three types of light diffusion plates. It is widely used in liquid crystal display, LED lighting and imaging display system.

Diffuser Sheet for LED Panel Light is one of the main applications in liquid crystal display. The light diffusion plate can be used in liquid crystal display mainly because of its heat resistance, flame resistance, light transmittance and other advantages, followed by light diffusion. The characteristics of the panel in the liquid crystal display, let us talk about these performance characteristics below.

Light source diffusivity: suitable for direct type backlight modules, with high brightness and high diffusivity, which can improve the uniform diffusion effect of the light distribution of the backlight source.

Light transmittance: Excellent light transmittance results in its high brightness.

Dimensional stability: Minimal water absorption, can still maintain good dimensional stability in a wet environment, and can be used normally in the temperature range of -40 ℃ ~ 125 ℃.

Antistatic property: It has good antistatic performance on the surface and prevents dust adsorption.

This is the performance of light diffusion plates in liquid crystal displays. It is precisely because of these characteristics that light diffusion plates are selected in liquid crystal displays.

UGR <19

The light diffusion plate may be a little strange to some people outside the industry, but it has been widely used in many fields like LED diffusion plates, PS diffusion plates, etc., so the following will perform a simple analysis. Today, we mainly analyze the production principle of light diffusion plates. After we understand its production principle, we can more easily apply it. Then the light diffusion plate is mainly processed by some technological means, and the principle used is mainly: once the light encounters an object that is not equal to its density during the irradiation process, it will form reflection or refraction. Light diffusion plates, led diffusion plates, etc. also use this principle, and then pass some basic plates, such as: PP, PS, etc., because the range of light reflection or refraction is not large, we can add on the surface of the plate Some diffusing agents so that you can view it from multiple angles and also more comprehensively.

Of course, we can also use its principle to change the light emission path artificially, which can satisfy more of our effects. We also have UGR <19 on sale, welcome to consult.

评论

发表评论