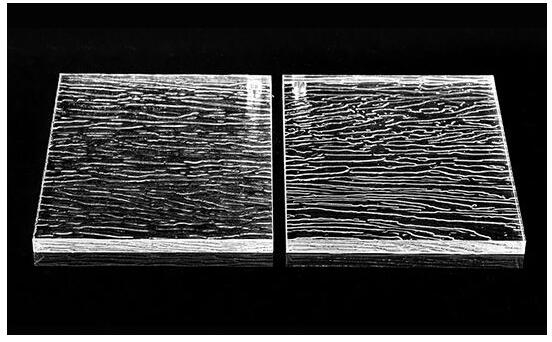

Although acrylic and Plexiglas polycarbonate are often seen as direct competitors, they have so much in common on the surface that at first glance you may not be able to tell the two apart, so how do you choose between them?

Colors

Polycarbonate offers a much smaller selection of colors than acrylic. However, most standard colors are available.

However, unlike acrylics, polycarbonate's color clarity decreases over time and can take on a yellow color with continued exposure to UV light.

Cost

Polycarbonate is 35% to 300% more expensive than acrylics.

Processability

When forming acrylic and polycarbonate sheets, acrylic is more manageable, can be cut more efficiently, and has significantly less resistance, primarily when using power tools.

In contrast, polycarbonate excels at drilling, as it can be drilled anywhere on the sheet without causing 99% damage. Acrylic can withstand drilling, but is more likely to break the closer you drill to the edges.

Damage resistance

Plastics such as acrylic and polycarbonate are impressively resistant to strong impacts and can withstand most alternative materials. They are often compared to glass, which is always the clear loser.

Both plastics are very resistant to damage and can easily resist blows that would turn a sheet of glass into thousands of shards. Nevertheless, polycarbonate always outperforms glass in terms of impact resistance because it is always superior to both. Depending on how it is constructed, acrylic can be 10-30 times more resistant than glass, but will usually fall short of the strength exhibited by polycarbonate.

评论

发表评论