Prismatic light diffusers are available in 2 main thicknesses, approximately 3 mm and 4.5 mm. 3 mm material (called P12 or K12) has a prism depth of approximately 1.9 mm, while 4.5 mm material (called P15 or K15) has a prism depth of approximately 2.3 mm.

Both P12/K12 and P15/K15 provide good light control in situations where there is considerable glare. The key issue with prismatic forms is the span over which the material can be safely suspended. For 3mm material, the ideal maximum span is 600mm or less on the shortest side, while for 4.5mm material, the ideal maximum span is 800mm or less, but this can be extended with proper support in the middle and fixation of the edges.

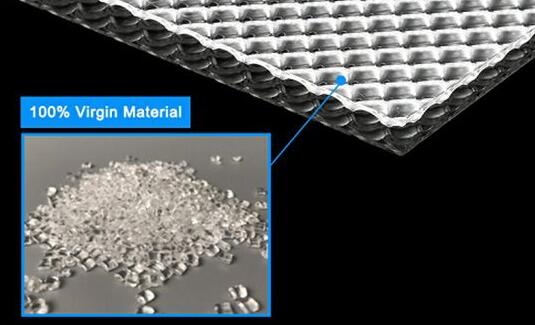

Although it is an excellent light diffuser, the prism tends to break easily if not handled with care. This is because it is this pattern that becomes involved in the material when extruded; in fact, making the material thinner and therefore more brittle than it would otherwise be. When working with larger prismatic panels, it is important to use proper framing, drilling or adhesives to reduce the chance of the material popping out in changeable weather.

The K12 Prismatic Lighting Panel is the most popular prismatic panel on the market. It provides significantly higher light transmission than traditional matte or orange peel pattern diffusion sheets while effectively suppressing glare values. It is both economical and efficient. This flat panel is customizable and its many options make it an excellent choice for a wide variety of lighting projects and environments. This type of prismatic panel is also available with a conductive grid that blocks a certain amount of electromagnetic interference. Please contact us for more information on this option.

评论

发表评论