Cost

While acrylic offers a high-end look, PVC laminates are a more economical option. They come in a variety of colors and textures, and have the added advantage of higher durability. However, if budget is not your concern, there is nothing more tasteful than acrylic.

Versatility

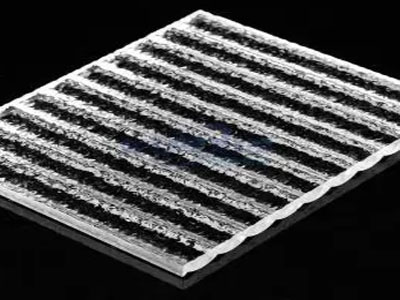

PVC laminates are available in a variety of textures such as matte, textured, metallic, glossy and super glossy. They are versatile in terms of color and pattern. Acrylics also come in a wide variety of colors and can maintain their glossy finish for years. However, make sure you know where to find a suitable alternative, as you may not always find the same shade on the market.

Acrylic Sheets

Maintenance and Durability

Acrylic finishes are scratch resistant and will not delaminate over the years, maintaining a seamless and glossy appearance over time. One of the disadvantages of this finish is that, due to its glossy nature, handprints are easily visible on it and require regular cleaning. Laminates, on the other hand, are more durable and stain resistant. They also have certain properties such as heat, UV and moisture resistance, and can be treated with antibacterial treatments.

Acrylic vs. PVC laminate. Advantages of both

A popular design strategy is to use a combination of acrylic and PVC laminate in the interior of a kitchen. PVC laminate is more suitable for the lower half of a modular kitchen because it can be handled frequently, while acrylic is ideal for upper cabinets. This enhances the look of the kitchen while greatly reducing your costs. pvc is also widely used for office cabinets.

For more information and help, Kunxin New Material Technology Co., Ltd is your best choose.We have Acrylic Sheets, contact us today to learn more about our options, and start experiencing their unique benefits.

评论

发表评论