The role of the acrylic diffusion plate is to make the light from the guide plate evenly diffused, there are also points of confusion. Acrylic light transmission rate is 92%, PC is 88%, ps is about 80%. Acrylic has a higher light transmission rate than PC and a lower cost, although its anti-ageing function is weak and PC data is precious and anti-ageing. Acrylic diffusion panels, by chemical or physical means, when refracted, the light encounters two different refractive indices in the centre of the act, resulting in physically imagined reflections and scattering. Adding inorganic or organic light diffusers to the substrate of the acrylic substrate, or reflecting and scattering the microscopic features in the array sequence of different refractive directions on the surface of the substrate.

Acrylic diffusion sheet with high haze, high light transmission, high looseness and other optical properties of plastic sheet, can effectively convert the point light source or line light source into a soft and uniform surface light source, in the premise of achieving excellent light transmission, with excellent light source dot matrix privacy, is the ideal optical material for secondary light distribution of LED lighting products, is a better light dispersion material for LED lighting products.

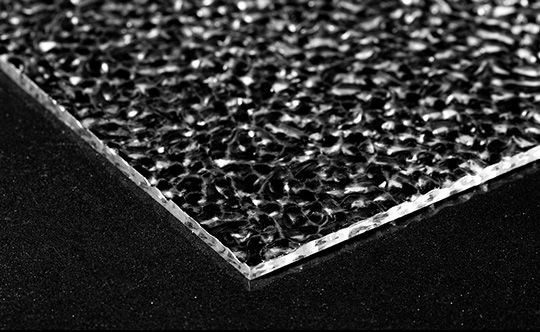

Textured Acrylic Sheet features

High brightness: with the same light transmission, the brightness is increased compared to traditional diffuser panels.

Excellent concealing effect: light source diffuses light evenly, excellent concealing light effect.

High limescale stability: low water absorption warpage and excellent limescale stability.

Excellent durability: not easy to turn yellow in accelerated UV ageing test.

We also have LED panel light diffusion sheet on sale, welcome to call us for more information.

Conventional acrylic diffusion sheets are usually mainly used as scattering particles involved in the chemical particles in the acrylic substrate. The light in the scattering layer is refracted and the two different media are constantly scattered in reflection and refractive index, producing light dispersion. Impact. However, this inevitably results in the absorption of light by the scattering particles and the utilisation of light energy is reduced. Frequently added chemical particles include organic light dispersants: inorganic light dispersants are mixed well.

A new microstructure acrylic diffusion sheet, a new microstructure, through its surface microscopic characteristics of the microarray to configure the structure, change the light path, so that the light through the different directions of refraction, as well as the uniformity of the incident light Shine effect. General micro-special structures include: A, V-slot sequence B, U-convex sequence C, prismatic array D, toroidal array e, micro-lens array micro-structure, high transmittance acrylic diffuse sheet, by changing the shape of the micro-structure, it can adjust different positions, divergence angle and spatial and energy distribution of the light field, attracted the attention of researchers. They realised the impact of the uniformity and transmittance of the light diffusing sheet.

Kunxin company Concerntrated on the produing of optical diffuser sheet for the lighting industry more than 10 year with exquisit technics.

评论

发表评论