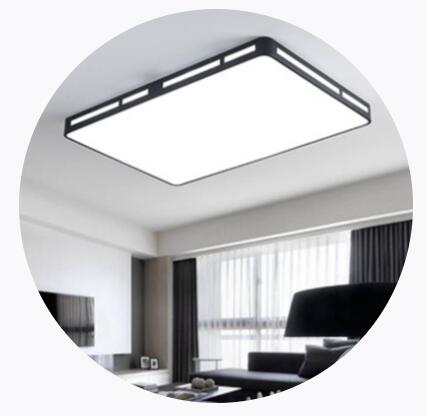

When decorating a room, in addition to some decoration materials, you also need to install lamps and lanterns. Because lamps and lanterns are very important in people's life and can provide lighting. In the dark night, you can work and live as in the daytime. In recent years, acrylic lamps are especially popular. There are many types of acrylic lamps, and people may not know how to choose when they are choosing. In this blog post, I will give you details on how to choose acrylic lights and what to look for when installing acrylic lights.

The advantages of acrylic lights

Color

The color is very durable. Acrylic panels are glossy, bright and colorful, and the colors are durable for 5-8 years. In other words, it will not change or fade in 5-8 years.

Transparent

High light transmission. Transparent acrylic sheets provide over 90% light transmission. The built-in light source provides uniform and soft nighttime brightness. Compared to neon, acrylic letters as a whole are luminous, not glowing like neon, and softer than neon.

Light source

Built-in light source. No need for external wiring, not easy to damage. First of all, there is no external wiring, which solves the problem of unsightly appearance of neon wiring. It also solves the problem that the wire and light source are exposed to the air and easily short-circuit and catch fire. And because of the good sealing performance of acrylic, it solves the problem of not being able to open the light in rainy days, so it can be used as usual in rainy and snowy days.

Word light consistent

Acrylic letters and light boxes have a good consistency. On this point, the molding of acrylic letters and light boxes is thermoforming. After the acrylic diffusion plate is heated, it is formed by various molds in one compression or blister, so several sets or pieces of the same mold are the same. In addition, as long as the color of two panels of the same color number is very consistent, it is almost indistinguishable to the naked eye. In both senses, the consistency of color and specification is conducive to the enhancement of the merchant's corporate image, as well as the unity of the merchant's decoration and store decoration style.

Body

Stable physical properties and strong resistance to high and low temperature deformation, which is also one of the important characteristics of acrylic for the outdoor industry. First of all, it has a strong resistance to ultraviolet rays, which is one of the reasons why it does not fade. In addition, it can withstand high temperature of 70℃ and low temperature of 50℃. It will not deform in this interval. This temperature difference does not occur in most areas of China, so businessmen can use it with confidence when it is outdoors.

Installation precautions

● Use pre-built bolts, or fix with shrink bolts, nylon plugs or plastic plugs; Match the load capacity with the weight. Ensure sturdiness, reliability and long life.

● Select the bolt specifications according to the product process; the hole diameter and burial depth must be consistent with the bolt specifications.

● The number of bolts or screws used for fixing should not be less than two, and the center of gravity of the lamp should match the center of gravity of the bolts or screws; when the diameter of the insulation table is 75mm or less, one bolt or screw is used for fixing.

● When the high temperature part of the lamp surface is close to combustible materials, heat insulation or heat dissipation measures should be taken.

How about acrylic lampshade

What is acrylic lampshade

Acrylic lampshade is made of acrylic material. Many friends may not know what acrylic is. Acrylic is actually a kind of organic glass, is an early development of an important thermoplastic, with good transparency and chemical stability. And weather-resistant, easy to dye, easy to process, beautiful appearance, in the construction industry has a wide range of applications. Acrylic lampshades also have some of the functions of acrylic materials.

Due to its excellent toughness and good light transmission, early used in the manufacture of aircraft windshields and tank sight glasses. Modern acrylic material surface coated with high-intensity ultraviolet absorbers, with a variety of colors. Night color is bright and very penetrating. It is resistant to sun and rain, and has a long service life of more than ten years. It is currently the most popular in the world. One of the materials used to make outdoor signs.

Acrylic lampshade characteristics

In the process of LED lights gradually accepted by the market, the problem of lampshades has been plagued by lamp manufacturers. It is necessary to have both a high light transmission rate as a prerequisite and a considerable light diffusion rate and good concealment of the light source. Initially the lampshade using glass, but the glass is not fragile, light diffusion effect is not very good, it is difficult to meet the lighting requirements. Later gradually developed to use resin instead of glass, but if only transparent resin lampshade, although the light transmission rate is high, basically can reach more than 90%, but the light diffusion effect is not ideal, and the concealment of the light source is poor. The light transmission rate of white resin is too low.

Acrylic diffusion sheet is made in the production process, the optical grade PMMA particles in the scientific addition of light diffusion agent components. Its core technology is the use of scientific production process, so that the diffusion plate is evenly distributed within the plate. When light passes through the plate, it encounters diffuse particles that produce optical effects such as refraction, reflection and scattering, so that light passes through efficiently, evenly and softly. Through the board without exposing the light source.

评论

发表评论